If I really like you

I will in person create a cake for you to fill your heart with sweetness

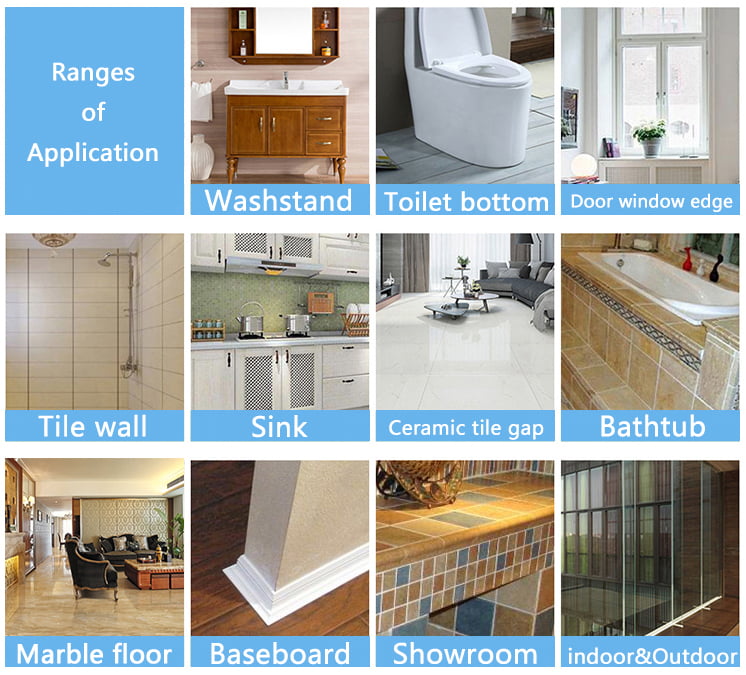

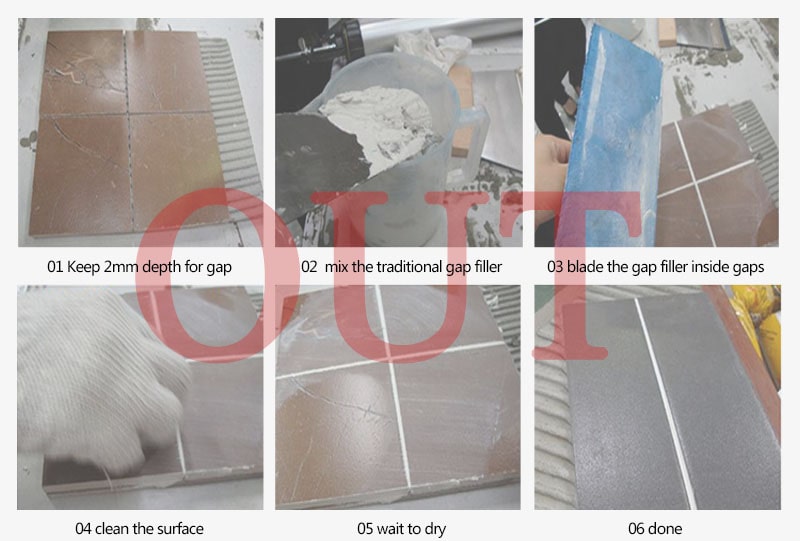

I will in person grout an exquisite gap for you are doing not let the ceramic tile gap turning black to damage your health

I want you to grasp

My love for you'll fill each gap between tiles and your heart

You are a careless person, invariably forgot their area unit several issues haven't resolved nonetheless.

You didn’t notice that the ceramic tile’ gap had already been dark and stale.

In a silent hour, they're whispering, heavy of black and darkness.

Originally beauty and white tile gaps are choked with dirt and mold.

When you area unit recent, United Nations agency can extremely love the tile gap dirty recent appearance? United Nations agency will extremely care regarding your health?

In fashionable society, that tile grout can honestly announce it will keep new for thirty years?

I am Kastar Tile Grout, I will say that,

I will accompany you to adulthood

I will keep one's hands off from darkness and stale.

I am thirty years anti-mildew guarantee.

I want to mention to tile:

Epoxy organic compound, pigments, and hardener area unit my staple, I even have twenty-six colors to suit for your completely different “makeup”

Because I need to remain by your aspect for an extended time to create the foremost lovesome confession.

This “companion” will face up to cerium, the EU environmental protection standards,

There is still no concern of the ROHS take a look at, it makes American state additional environmentally friendly and additional reliable!

If I really like this tile, I need to accompany her on a daily basis and night, and that I need to create a promise to her — an exquisite gap, which incorporates concentration and persistence —- with my presence, it'll cause you to stunning whole life